My master’s thesis explores the possibilities of folded mechanisms for architecture.

The aim was to find and optimise a folding pattern so that it turned into a system that could actually be build. For this several criteria had to be satisfied: it had to be rigid-foldable, flat-foldable, and also confine a space when deployed. Additionally, the structure should be able to carry its own weight at least at certain scales. After choosing a pattern, a thorough analysis was conducted to find the best way of accommodating the thickness of the panels as this proved to be difficult for the chosen pattern.

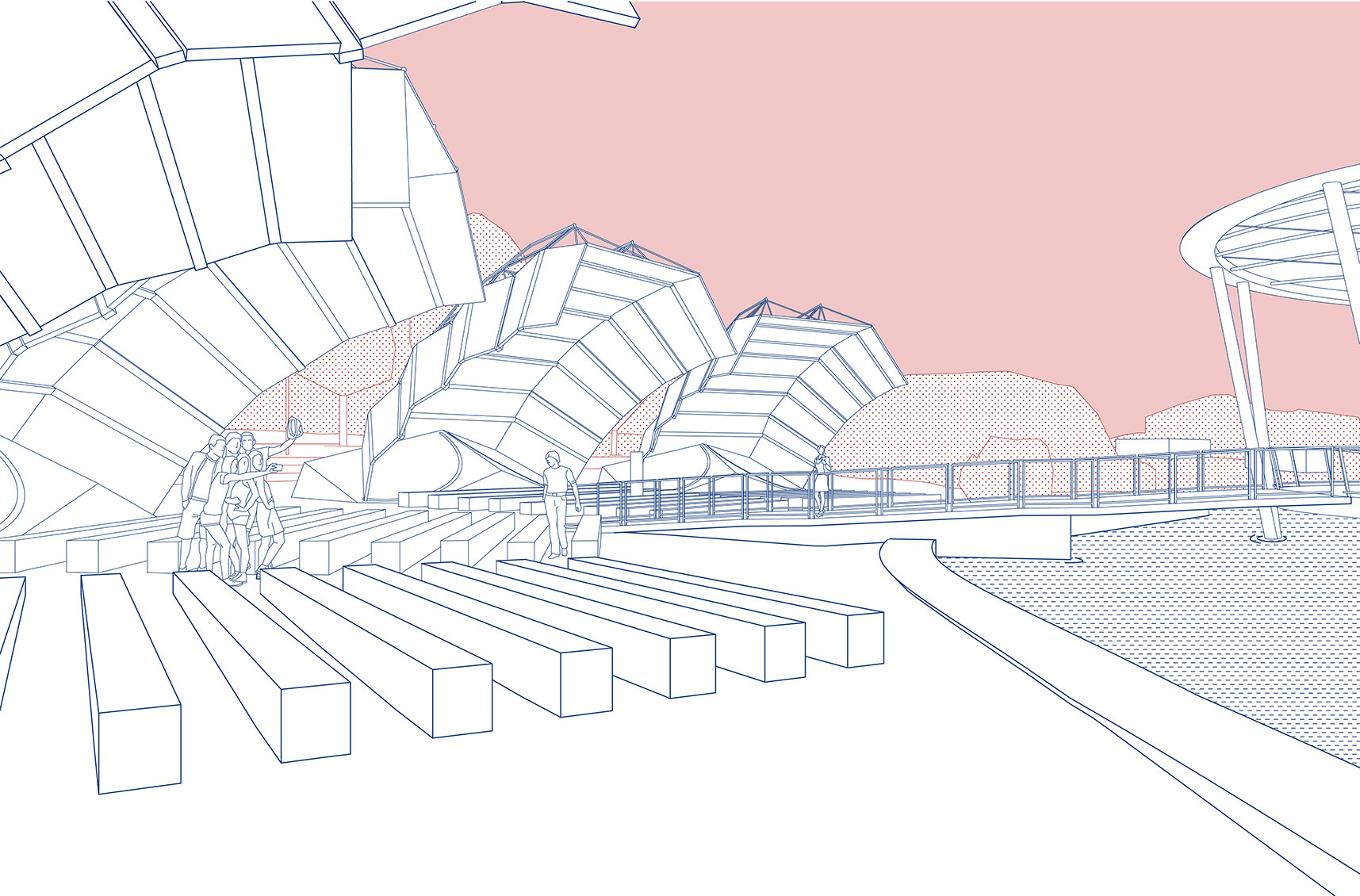

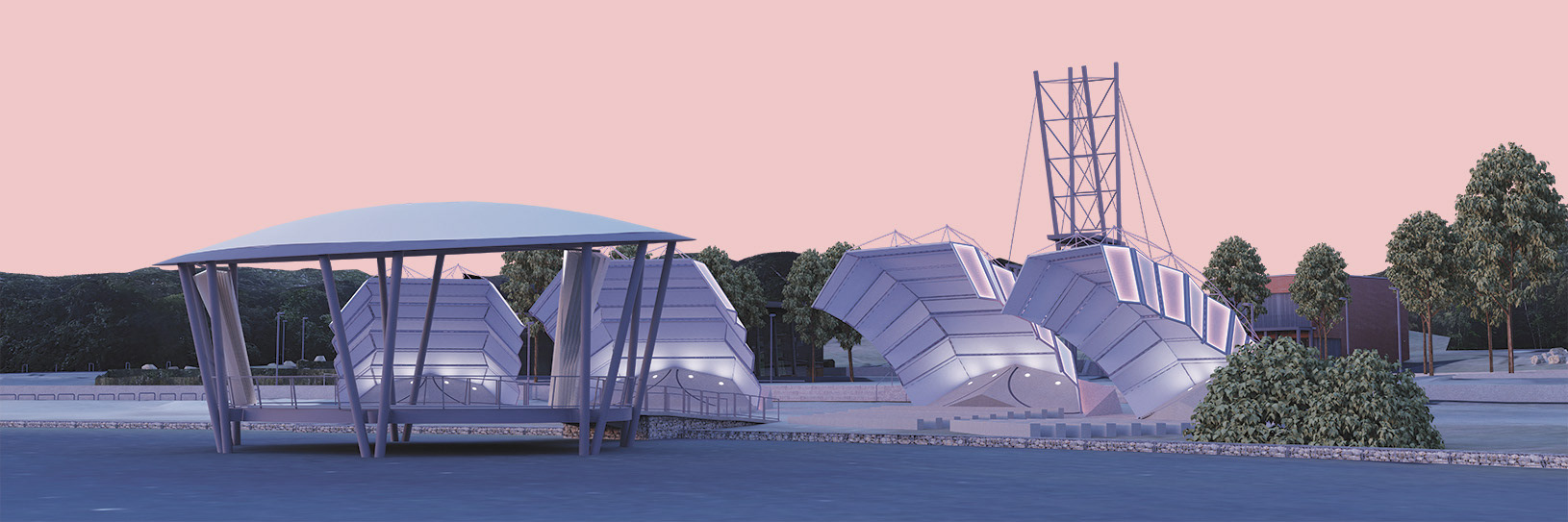

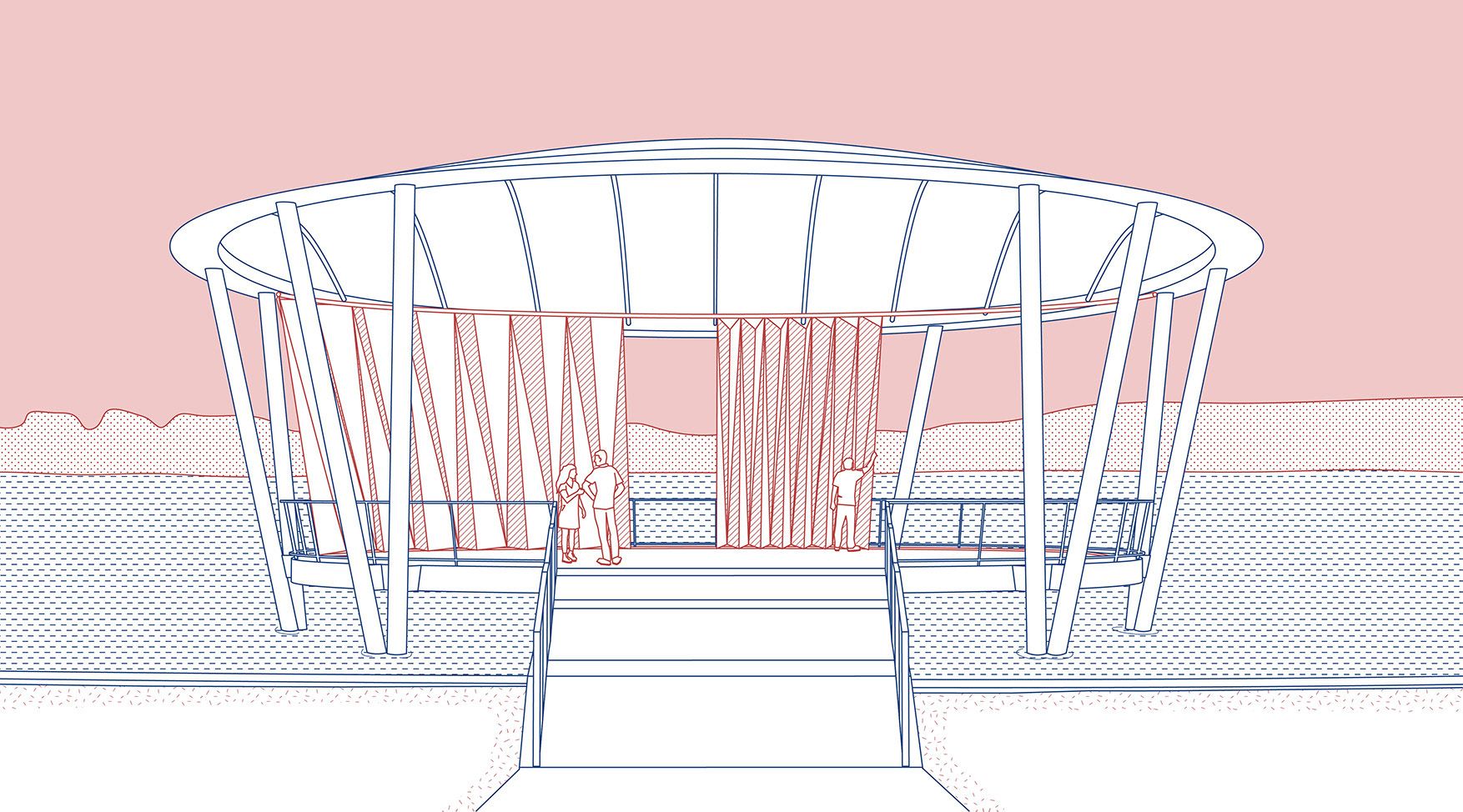

The design was then applied to a real-life example, the lake stage at Blausteinsee in Eschweiler. The former mining area for brown coal was restored as a lake and nature reserve in the nineties and in 2008 a stage and an observation platform were added along with some gastronomical and educational facilities. But while the stage has a roof the area for the audience provides no shelter from rain or sun. This severely limits the potential of the stage since many events like theatre or music performances can only take place in perfect weather conditions. Simply installing a roof would however generate other problems as it would limit the view from the observation platform. This calls for a convertible system and that makes it the perfect opportunity to demonstrate the strengths of folding structures.

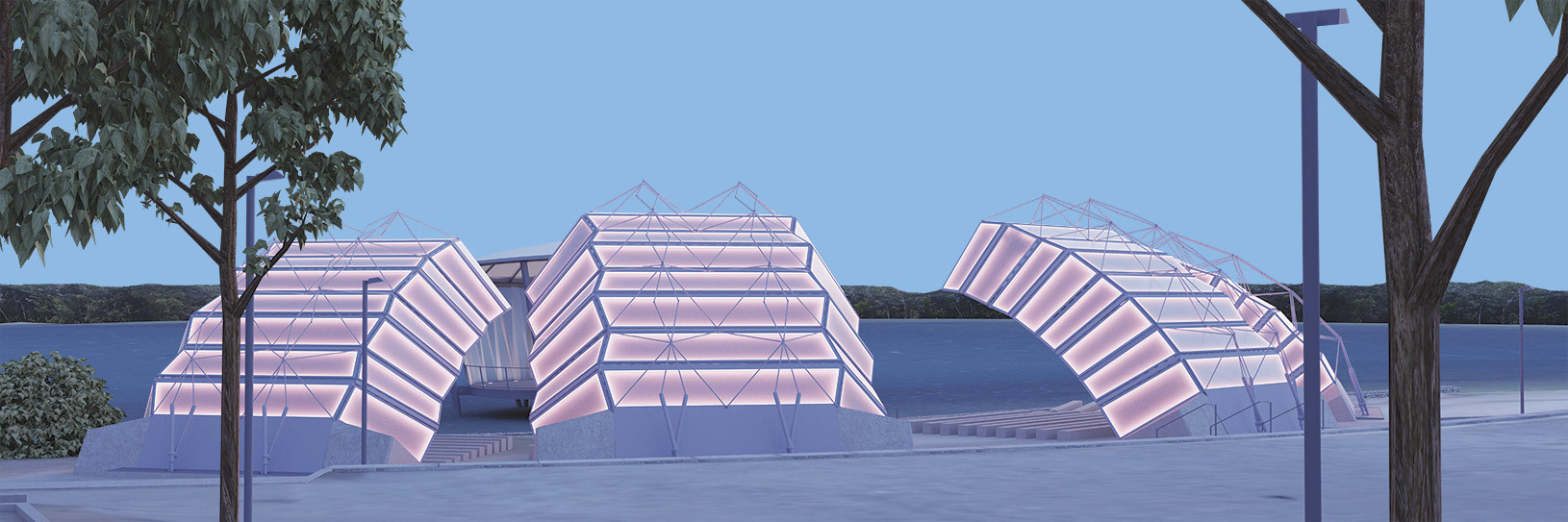

The design acts as both the main structural element as well as the building shell. No further stationary elements are needed. To support the folding plates several bars are added on the back side of the structure. Their movement is driven by the folding motion of the plates. These bars are necessary because of the relatively large span of approximately ten meters. The mechanism is driven by two different actuators: the start of the opening process is controlled using a scissor mechanism, while the lateral movement of the side panels has its own drive. Theoretically either of them could control the whole process, but to prevent straining the materials the best actuator for each part of the opening process has been chosen. The details have been planned accordingly.

The structure is made of steel frames that are covered in aluminium on the bottom and polycarbonate on the top. This allows the design to be lit from the inside as led strips can be attached to the inner rim of the steel frames. Lastly, the stage received a movable background that picks up on the folding elements in the audience and considerably improves acoustics. It can be moved by hand and can thus be used as part of the stage setting in theatrical performances.